A - Master File

It begins by listening to you, our customer. We’ll identify your needs, innovate the approach, application and methods to better create a custom engineered solution to your requirements that outperforms conventional systems. BASX draws on the knowledge base from an experienced team from every sector of industry, whether your needs cover Commercial HVAC, Data Center, Cleanroom or Seismic needs, each BASX product stands alone against the industry standard.

HEADER Styles

This is a Header H1

This is a Header H2

This is a Header H3

This is a Header H4

This is a Header H5

This is a Header H6

Paragraph Class Styles

Let's look at a paragraph Class - p.h2

Let's look at a paragraph Class - p.h3

Let's look at a paragraph Class - p.h4

Let's look at a paragraph Class - p.h5

Let's look at a paragraph Class - p.h6

Let's look at a paragraph Class - p.h7

Let's look at a paragraph Class - p.h8

Each custom suite is designed around your building needs rather than asking you to adapt to a pre-defined container. Due to our integral truss design, we are able to offer wide open, column free space with high ceilings that allow for a natural work environment.

The end result is customized grow facility that ensures the fastest speed to market, with pricing that is competitive with traditional “space within a space” tenant improvement or new construction build out; all within a superior agricultural production environment.

- Custom designed grow suites are manufactured and designed to integrate modern clean room technology into the most state-of-the-art controlled environment agriculture system.

- Integrated systems and controls born from semiconductor, biotech and life science industry technologies that control contaminants, air quality and composition, mold and bacteria, humidity, CO2 and irrigation.

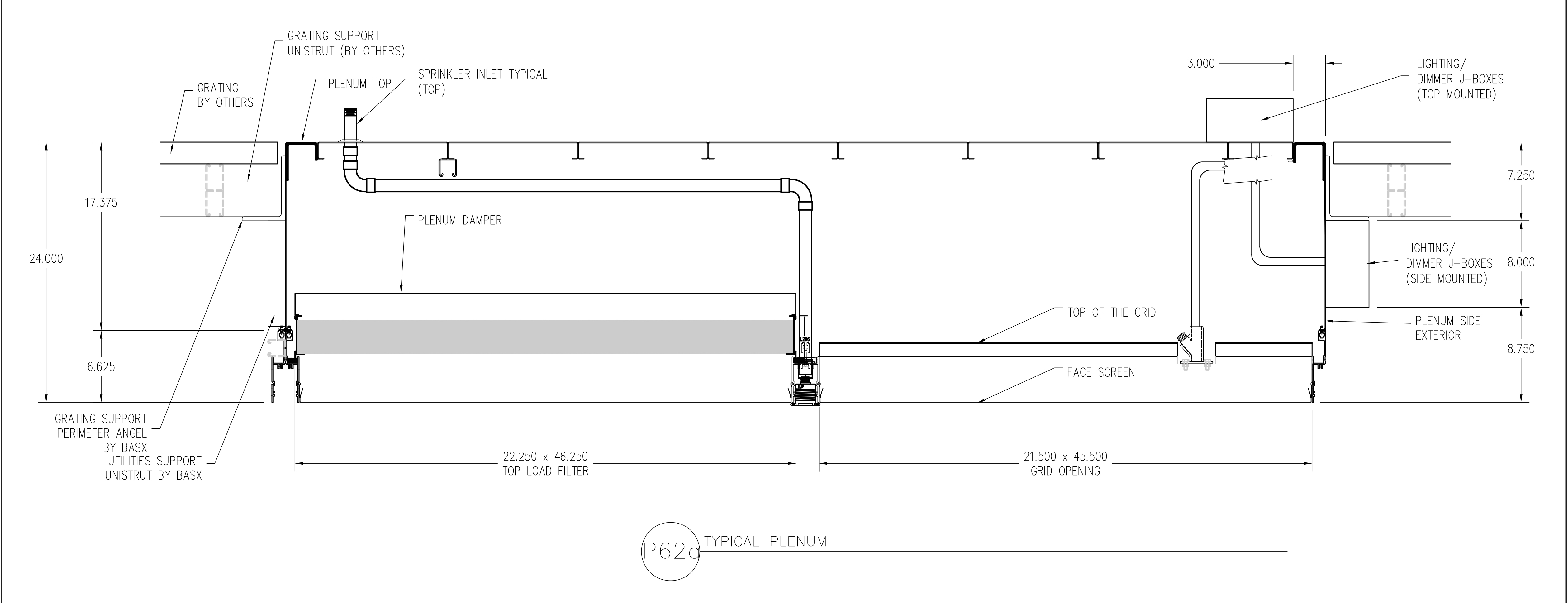

- Cleanroom Style Design with isolated AC equipment room and large area MERV 13 carbonless filters.

- Column free wide open space allows for optimal use and flexibility of controlled space.

- Compact design optimizes building's free space.

- ETL labeled assembly meets local codes.

- Scalable, modularly designed system allows for expansion and relocation to eliminate sunk tenant improvement (TI) costs.

Kind with your Pocket

Economical alternative to Hardwall panel construction

Exclusive Uni-Grid System

Exclusive Uni-Grid load-bearing, walkable ceiling system allows for easy maintenance and interchange of lights, tiles and HEPA filters.

Unlimited sizesand configurations

Available in an unlimited number of sizes and configurations using high quality standard components

Resistant Finish

Baked polyurethane powder coat finish ensures non-outgassing components with a hard-shell finish that will withstand frequent cleansing and will not contaminate your process

Maximum Flexibility

Truly modular non-progressive construction provides maximum flexibility to accommodate new processes and equipment

Fast Installation

Fast installation, simple to relocate, and pre-engineered to meet your demanding schedule.

Structural Integrity

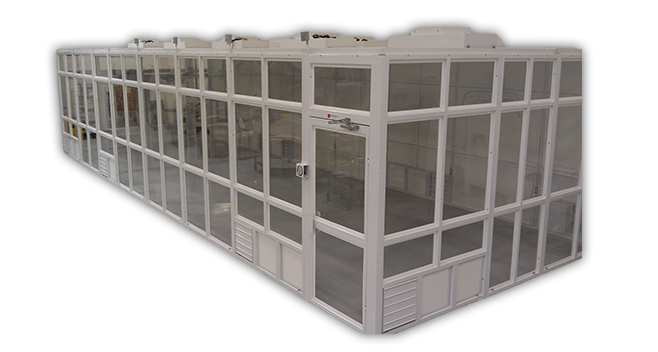

BASX Modular Stretchwall Cleanrooms stand out as the most structurally rigid available anywhere in the industry. Formed from cold-rolled tubular steel, each frame is incredibly robust and highly durable. Together with any of the available flexible PVC stretch panels and our exclusive ceiling system, the frames compose a room which can be seismically rated and will endure punishment from outside and within.

Cleanliness and Durability

All BMC frames and ceiling grids are powder coated with a polyurethane material then baked at 450 degrees to ensure truly non-outgassing components. Unlike epoxy, which is an outgassing product, or unbaked powder coatings, the BMC process provides an extremely hard-shell finish that will withstand frequent cleansing and will not contaminate your process. The result is a beautiful, consistent finish on a room that looks simple even though it meets detailed requirements.

Unique and Intelligent Design

BMC's exclusive Uni-Grid ceiling system is fully welded to form a structurally superior and unified ceiling grid. It is then powder-coated and fitted with closed-cell gasketing that creates a tight seal with all drop-in components. Each fully loaded Uni-Grid is self-supporting and can be designed to be completely walkable with a 250 lb point load, allowing for simple exchange of the 2'x4' lights, tiles and Fan Filter Units.

Options

- Factory installation of provided items

- Stretch panel materials include: clear, static dissipative, UV protectants, opaque white, black/green and black, as well as other application-specific materials

- UL listed flush-mount electrical outlets and light switches

- Pass-thru’s, air-showers

- Teardrop or flow-through lighting

- Cutouts to accommodate processes, conveyer belts and machinery

- Structural calculations and seismic ratings

- Integrated gowning room

- Swing doors, Automatic Sliding Doors, sliding track curtains or strip access entrances

The BASX Modular Cleanroom Advantage

- Unique Uni-Grid load-bearing, walkable ceiling system can span up to 40 feet without the need for additional down posts.

- Baked polyurethane powder coat finish ensures non-outgassing components with a hard-shell finish that will withstand frequent cleansing and will not contaminate your process

- Cleanable surfaces.

- Truly modular design with ultimate flexibility in materials and configurations to meet performance and budget requirements.

- Fast, easy assembly to get you up and running as quick as possible, and the ability to expand or modify as your needs grow.

- Class 10 to 100,000 and USP 797 capable.

Fast Lead Times

BASX’s Modular Cleanroom Specialists are able to design and build your custom modular cleanroom to your specifications with rapid lead time. On site installation can be completed in just a few days, minimizing disruption in your warehouse and production facilities.

Industries and Applications

- Injection Molding

- Medical Devices

- Medical Device Packaging

- Food Grade

- Microelectronics

- Pharmaceutical

- Biomedical

- Medical Device

- Injection Molding

- Photonics

- Research & Development

- Automotive

- Aerospace

Specifications

- Size

- Innumerable configurations, in standard increments of 2’x4’ units, unsupported spans up to 40’ with Truss System.

- Class

- Federal Standard 209e Class 100,000 to Class 10 and ISO Standards compatible.

- Filtration

- 2'x4' HEPA or ULPA Fan Filter Units. Various Control Packages Available.

- Ceiling

- Uni-Grid ceiling system: 1/8” thick steel , all-welded construction, fitted with closed-cell gasketing.

- Frames

- Welded 2”x2”x.083” heavy gauge cold-rolled tubular steel, pre-engineered construction.

- Finish

- White baked polyurethane powder-coating.

- Stretch Panels

- 16 mil clear flexible PVC standard.