Cleanroom Ceiling Systems

Leo nullam dictum elit tempus quisque euismod placerat quam metus aliquet blandit lacus in.

Praesent hac tortor interdum fringilla nibh libero mauris ullamcorper eleifend diam himenaeos semper augue.

Eu varius mi vulputate litora ipsum fringilla porttitor est sed facilisis massa.

Congue congue in pharetra neque erat libero tincidunt habitasse odio nunc fames curabitur placerat curabitur.

Pellentesque ad tortor bibendum vestibulum lectus volutpat magna fermentum venenatis.

Ceiling Systems

Etiam etiam consectetur viverra phasellus vestibulum mollis diam at purus non lacinia litora.

Sodales risus lobortis potenti malesuada aenean sagittis pellentesque blandit aliquet fusce libero.

Tincidunt primis sollicitudin suscipit magna sagittis sapien fusce risus lobortis sagittis ipsum.

Plenum Modules

Etiam etiam consectetur viverra phasellus vestibulum mollis diam at purus non lacinia litora.

Sodales risus lobortis potenti malesuada aenean sagittis pellentesque blandit aliquet fusce libero.

Tincidunt primis sollicitudin suscipit magna sagittis sapien fusce risus lobortis sagittis ipsum.

Plenum Modules

Etiam etiam consectetur viverra phasellus vestibulum mollis diam at purus non lacinia litora.

Sodales risus lobortis potenti malesuada aenean sagittis pellentesque blandit aliquet fusce libero.

Tincidunt primis sollicitudin suscipit magna sagittis sapien fusce risus lobortis sagittis ipsum.

Plenum Modules

Etiam etiam consectetur viverra phasellus vestibulum mollis diam at purus non lacinia litora.

Sodales risus lobortis potenti malesuada aenean sagittis pellentesque blandit aliquet fusce libero.

Tincidunt primis sollicitudin suscipit magna sagittis sapien fusce risus lobortis sagittis ipsum.

Plenum Module

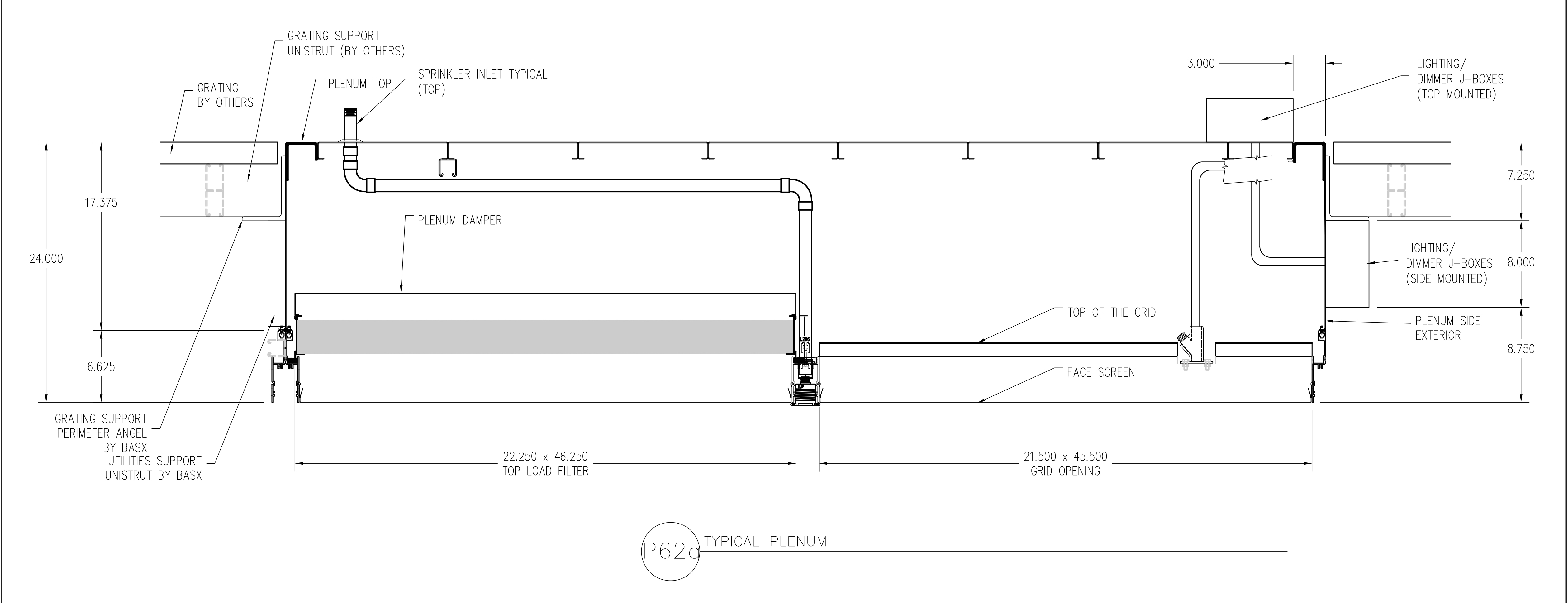

Plenum modules eliminate the need for field built ducts and duct collars while reducing overall pressure drop. Plenum modules have the same benefits as flush ceiling grid, including integrated lighting and fire protection, as well as excellent performance. Able to withstand high point loads with minimum deflection, BasX plenums are able to support recirculation air handlers, live loads and other accessories. Maintenance access to fan modules is made easy via walkable top skins. Multiple plenums may be tied into one fan module when side wall openings are used.

This is the title

- Provides Direct Support For Recirculation Air Handlers

- Plenum Module Eliminates The Need For Field Built Plenums

- Shared Air Openings To Adjacent Plenums

- Plenum Modules Are Suspended From Structure Or Custom

- Floor Mounted Support Structure Can Be Provided

- Plenum Modules Are Available In Sizes Up To 8’ x 24’

BASX Solutions offers plenum systems with a flush LED light grid system, sprinklers and various grid options; including powder-coated aluminum top-load gel grid and both powder-coated aluminum and stainless steel bottom load grid.

Supply Air Options:

- Ducted supply air to each plenum module (side or top).

- Recirculation Air Handlers mounted on top of plenum modules.

- Fan filter units installed into each plenum module.

BASX Solutions offers a Fan Powered Plenum System with bottom-load stainless flush grid. This System includes a stainless steel or powder coated steel plenum, EC Fan Motors, LED Lighting and sprinklers. We can also incorporate a return air plenum for a complete supply and return air system to provide laminar air flow throughout the space.

features

- Stainless Steel Bottom Load Flush Ceiling Grid

- Stainless Steel or Powder-Coated modular welded galvanized steel plenum boxes

- LED Lighting

- Sprinkler System (Optional Flush or Pendent Type)

- Cleanscreens

- EC Fans with Mod-Bus Controls (Various control options available)

- HEPA/ULPA Filters with dampers

- System(s) to be supported from structure above or floor-supported option available.

- Return Air Plenum System mounted on top of the supply plenum box (Optional)

- Sensible Cooling Coils (Optional)

- Plenums are factory wired for lighting and fan motors to a single j-box mounted on the plenum.

Grid Systems

Summary

- Content

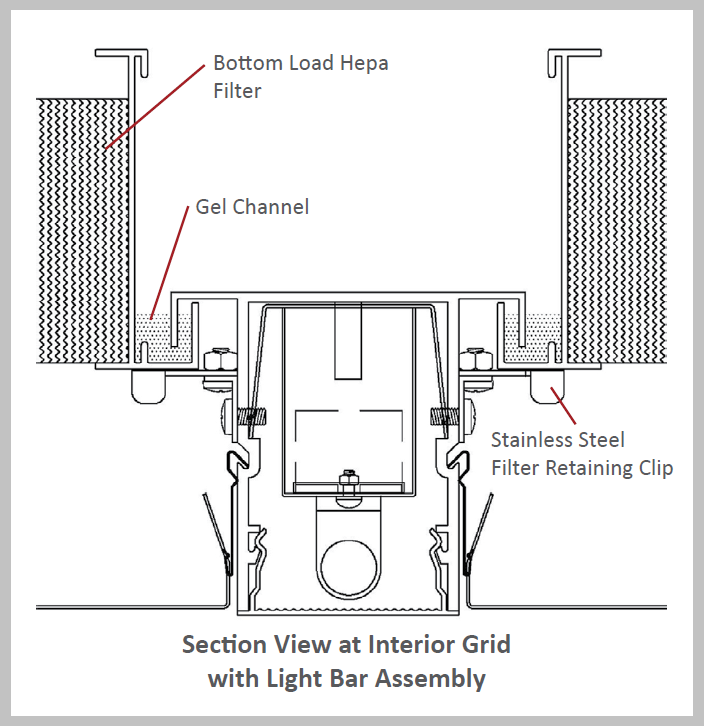

BASX Solutions offers a flush ceiling system with a Bottom-Load Flush ceiling. This extrusion is suited for applications where the space above the ceiling grid is limited and where the application calls for the filters to contain gel rather than the ceiling grid. It enables you to load filters, fan filter units, or blank pans straight up without tipping or rotating them through the grid opening. The extrusion features a downward facing knife-edge to which the gel in the filter or blank pan will seal.

Features:

- Integral knife-edge extrusion.

- Welded module grid with welded knife-edges miters. Optional stick-built grid with field caulked miters where required.

- Continuous slot extrusion for the retaining clips allows for superior load capacity.

- ¼ turn filter retaining clips that do not generate particles (we do not use a screw receiver extrusion since it generates particles).

- Closure strip for the slot to eliminate particle cavities.

- A true flush concealed sprinkler head can be used in the grid extrusion.

- Filters that are pre-gelled at the filter manufacturer’s facility.

- Option to be walkable on the filters, FFUs, or blank pans.

- Optional Equalizer can be used to balance the system with a center adjustment port in the filter.

- Of course, this system includes all the features and options of the flush ceiling, integrated lighting, built-in fire protection, Clean-Screens, welded modular grids or stick-built grids, modular plenums, and special finishes for chemical resistance.

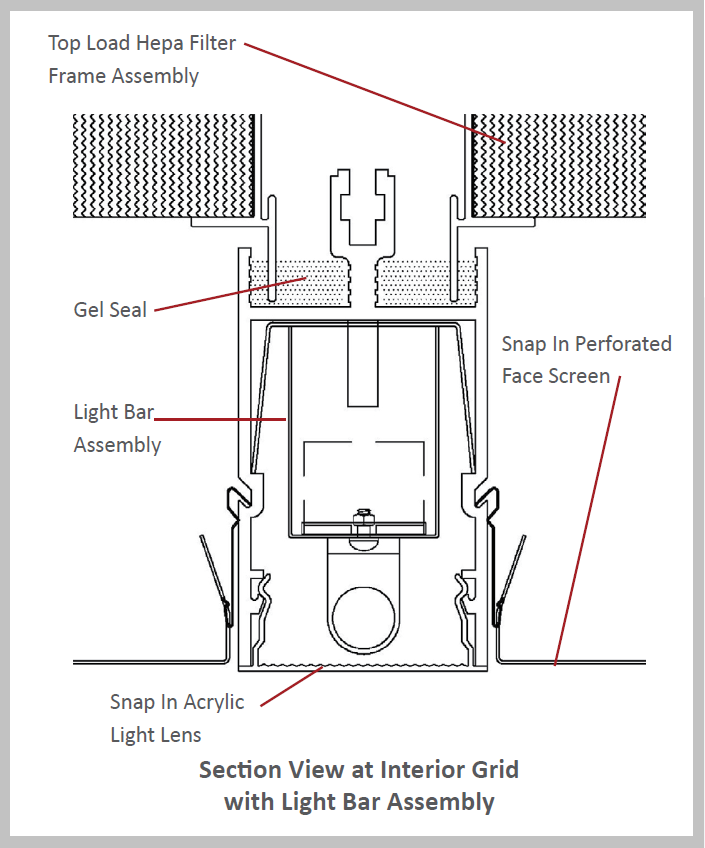

BASX Solutions offers a flush ceiling system with a Top-Load Flush ceiling. This extrusion enables you to load filters, fan filter units, or blank pans up through the grid and sets down onto a gasket or gel seal.

Features:

- Gasket or gel seal available.

- Welded module grid with welded knife-edges miters. Optional stick-built grid with field caulked miters where required.

- Continuous slot extrusion for the retaining clips allows for superior load capacity.

- turn filter retaining clips that do not generate particles (we do not use a screw receiver extrusion since it generates particles).

- Closure strip for the slot to eliminate particle cavities.

- A true flush concealed sprinkler head can be used in the grid extrusion.

- Filters that are either gasket or gel seal.

- Option to be walkable on the filters, FFUs, or blank pans.

- Optional Equalizer can be used to balance the system with a center adjustment port in the filter.

- Of course, this system includes all the features and options of the flush ceiling, integrated lighting, built-in fire protection, Clean-Screens, welded modular grids or stick-built grids, modular plenums, and special finishes for chemical resistance.

The stainless steel grid system is a bottom load gel system. Includes LED lighting, integral sprinkler connections and cleanscreens. Available in both 304 and 316L stainless steel. This stainless steel grid system is fully welded and capable of shipping up to 8’ x 20’ modules. The HEPA/ULPA filters are pre-gelled and shipped to the job site for installation into the bottom load grid; knife edge of grid is a downward extrusion to accept the pre-gelled filters.

Specifications

- Size

- Innumerable configurations, in standard increments of 2’x4’ units, unsupported spans up to 40’ with Truss System.

- Class

- Federal Standard 209e Class 100,000 to Class 10 and ISO Standards compatible.

- Filtration

- 2'x4' HEPA or ULPA Fan Filter Units. Various Control Packages Available.

- Ceiling

- Uni-Grid ceiling system: 1/8” thick steel , all-welded construction, fitted with closed-cell gasketing.

- Frames

- Welded 2”x2”x.083” heavy gauge cold-rolled tubular steel, pre-engineered construction.

- Finish

- White baked polyurethane powder-coating.

- Stretch Panels

- 16 mil clear flexible PVC standard.