Integrated Operating Systems iOR

Cleanroom Technology Adapted to Hospital Requirements

How it Works

- Laminar air exiting iOR is no different than conventional established patented cleanroom design

- Directly supported from building structural and fed with air handlers

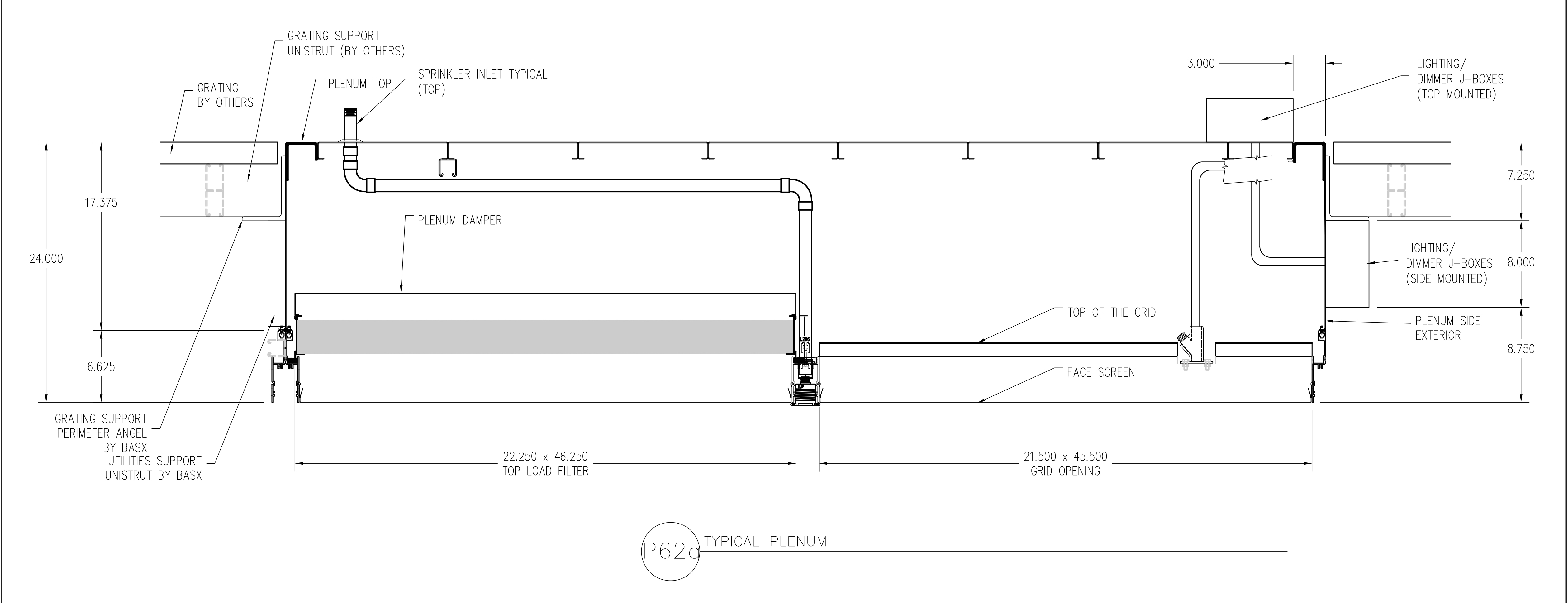

- Modular design Incorporates structural, lights, hepa filters, air balance dampers, discharge screens, and quick connect wiring for easy install

The ceiling system is comprised of four sections

Custom manufactured solution tailored to customers’ site-specific

OR requirements integrating architectural, MEP, structural and controls

Benefits of iOR

- Integration of structural components into plenums

- Customization to support lights, instruments, and video screen booms supported directly from iOR system

- Internal air control and external frame

- Ability to support dynamic loads directly from grid

- Hybrid room challenges solved using integrated structural design

- Modular design that eliminates multiple field trades and transfers ownership to single point responsibility

Benefits to the client

- Reduced HAI’s

- Coordination ease with iOR

- Elimination of multiple trades

- Space allocations above the ceiling

- Reduces design coordination between disciplines

- Site install coordination and manpower overlap significantly reduced

- Modular design narrows equipment suppliers to single point responsibility

- Reduced time and cost of renovation of new surgical suites (50-75% reduction in time)

- Ability to integrate support for equipment directly into a structure than can be installed in a day

History & Evolution of the Surgical Suite

Integrated OR systems are necessary

for the following reasons:

- 90-99,000 deaths per year associated with Hospital Acquired Infections (HAI’s)

- Insurance and Medicare not paying for HAI’s

- Public awareness

- Construction Cost and Lead-time

- Hospital cost control

- Patient and Staff safety

Our Process - Vertically Integrated