Modular Cleanroom Solutions

BASX Modular Cleanrooms (BMC) has been a recognized leader in the design and fabrication of truly modular cleanrooms backed by world class service to meet our customers’ requirements. We offer cleanrooms with the industry’s highest quality design to meet most cleanliness levels – from Class 10 to 100,000 and USP 797 – using the most cost-effective combination of construction materials. And we have the experience to support every phase of modular aseptic cleanroom design and construction to fit your particular budget and timeline. BASX’s Modular Cleanroom Specialists are able to design and build your custom modular cleanroom to your specifications with rapid lead time. On site installation can be completed in just a few days, minimizing disruption in your warehouse and production facilities.

BASX Modular Cleanroom Advantage

- Unique Uni-Grid load-bearing, walkable ceiling system can span up to 40 feet without the need for additional down posts.

- Baked polyurethane powder coat finish ensures non-outgassing components with a hard-shell finish that will withstand frequent cleansing and will not contaminate your process

- Cleanable surfaces.

- Truly modular design with ultimate flexibility in materials and configurations to meet performance and budget requirements.

- Fast, easy assembly to get you up and running as quick as possible, and the ability to expand or modify as your needs grow.

- Class 10 to 100,000 and USP 797 capable.

Cleanliness and Durability

All BMC frames and ceiling grids are powder coated with a polyurethane material then baked at 450 degrees to ensure truly non-outgassing components. Unlike epoxy, which is an outgassing product, or unbaked powder coatings, the BMC process provides an extremely hard-shell finish that will withstand frequent cleansing and will not contaminate your process. The result is a beautiful, consistent finish on a room that looks simple even though it meets detailed requirements.

Unique and Intelligent Design

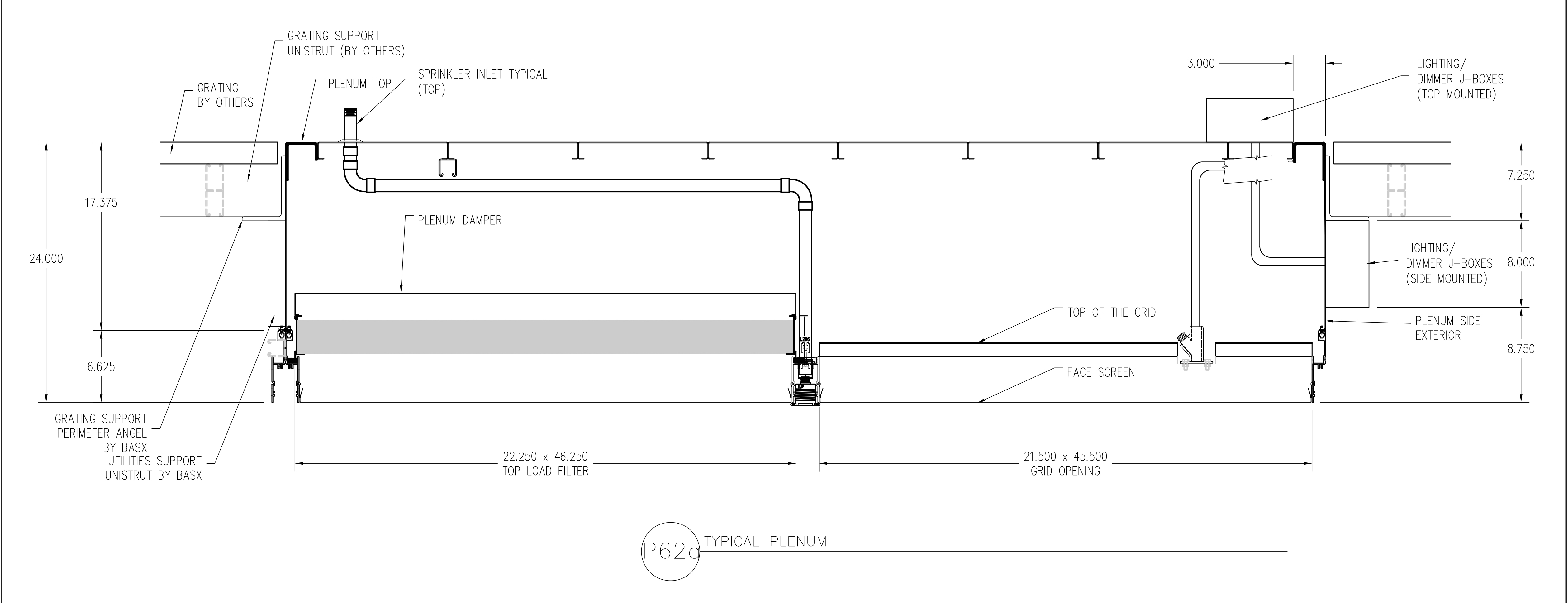

BMC's exclusive Uni-Grid ceiling system is fully welded to form a structurally superior and unified ceiling grid. It is then powder-coated and fitted with closed-cell gasketing that creates a tight seal with all drop-in components. Each fully loaded Uni-Grid is self-supporting and can be designed to be completely walkable with a 250 lb point load, allowing for simple exchange of the 2'x4' lights, tiles and Fan Filter Units.

Industries and Applications

- Injection Molding

- Medical Devices

- Medical Device Packaging

- Food Grade

- Microelectronics

- Pharmaceutical

- Biomedical

- Medical Device

- Injection Molding

- Photonics

- Research & Development

- Automotive

- Aerospace

Specifications

- Size

- Innumerable configurations, in standard increments of 2’x4’ units, unsupported spans up to 40’ with Truss System.

- Class

- Federal Standard 209e Class 100,000 to Class 10 and ISO Standards compatible.

- Filtration

- 2'x4' HEPA or ULPA Fan Filter Units. Various Control Packages Available.

- Ceiling

- Uni-Grid ceiling system: 1/8” thick steel , all-welded construction, fitted with closed-cell gasketing.

- Frames

- Welded 2”x2”x.083” heavy gauge cold-rolled tubular steel, pre-engineered construction.

- Finish

- White baked polyurethane powder-coating.

- Stretch Panels

- 16 mil clear flexible PVC standard.