Hepa Station Laminar Flow Work Bench

Structural Integrity

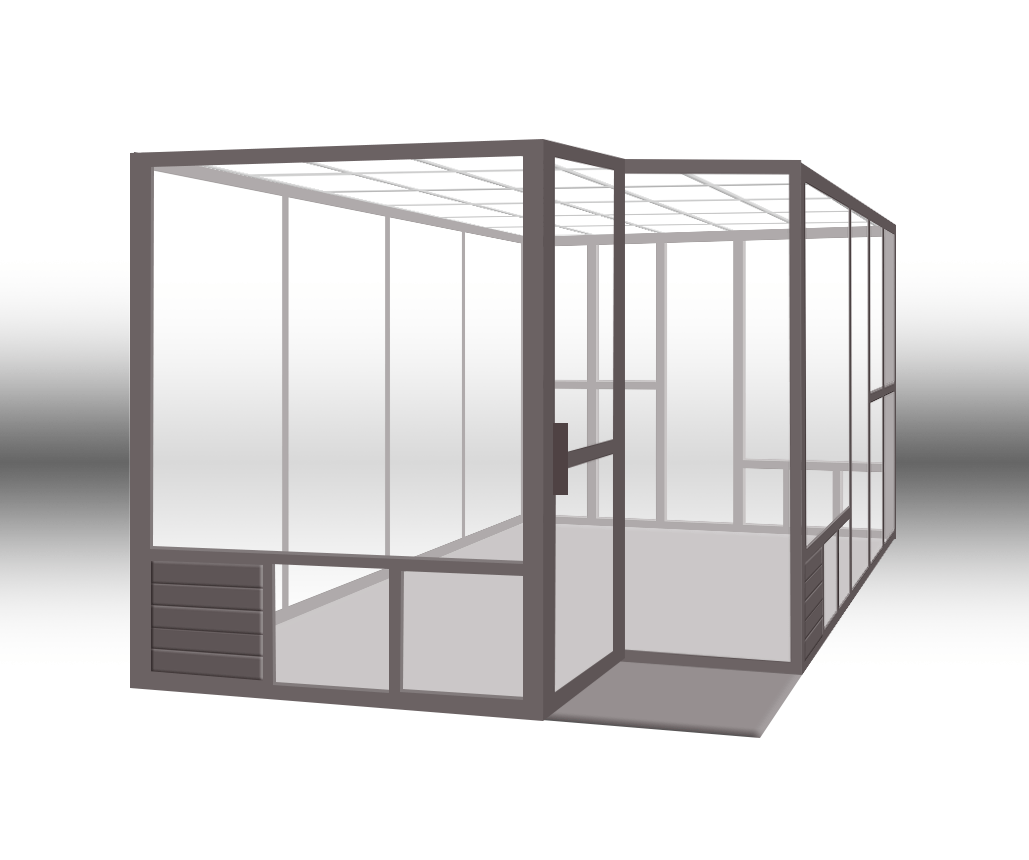

The HepaStation is composed of four frames (top, back, left side, right side), each of which is constructed of 2”x2”x.083” cold-rolled steel tube. Each frame is welded, powder coated with polyurethane, and then baked at 450 degrees. The frames are bolted together using heavy duty barrel nuts for a tight seal. The result is a highly rigid framework with a non-contaminating, non-particulating and chip-resistant surface.

The work area is enclosed with 1/4” thick, clear acrylic panels on the back and sides of the unit. The acrylic is secured using our CleanSeal attachment system for a tight seal. A 14” heavy gauge flexible PVC shield hangs from the front of the unit, directing airflow above the work surface.

Cleanliness and Durability

All BMC frames and ceiling grids are powder coated with a polyurethane material then baked at 450 degrees to ensure truly non-outgassing components. Unlike epoxy, which is an outgassing product, or unbaked powder coatings, the BMC process provides an extremely hard-shell finish that will withstand frequent cleansing and will not contaminate your process. The result is a beautiful, consistent finish on a room that looks simple even though it meets detailed requirements.

Unique and Intelligent Design

BasX Solutions’ HepaStation is a portable clean environment that allows individuals to work in a contamination controlled Class 100 environment. HepaStations can easily be placed within an existing cleanroom to isolate processes, or act as standalone workstations in unregulated environments. Designed for use with your own table, or with one of our optional built-in Stainless Steel tabletops.

Can also be used as a Class 100 Clean Air Garment Enclosure (C.A.G.E.) to extend the life of your cleanroom garments. The HEPA filter placed atop the unit bathes your cleanroom suits and smocks with 14 air changes per minute, which protects them from contamination when not in use. Offered with 12 or 24 captive hangers with spacers.

Units include necessary HEPA Fan Filter Units (1 each for 4’ unit and 2 each for 8’ unit) and cleanroom safe teardrop lighting. Each plugs into UL listed 20 amp switch controlled by outlets housed in the frame. One outlet is left available (approx. 17.6 Amps free once running) inside the work area and one outside for powering other pieces of equipment. The power switches control the fan/s and light separately, and are located on the top, front portion of the unit.

Optional Considerations

Though adjustable leveling feet are standard, convenient 4” Cleanroom locking-type casters are available for both units. Additionally, you may choose to purchase one of two built-in tabletops; solid 14 gauge 304 stainless steel or perforated 14 gauge 304 stainless steel.

Specifications

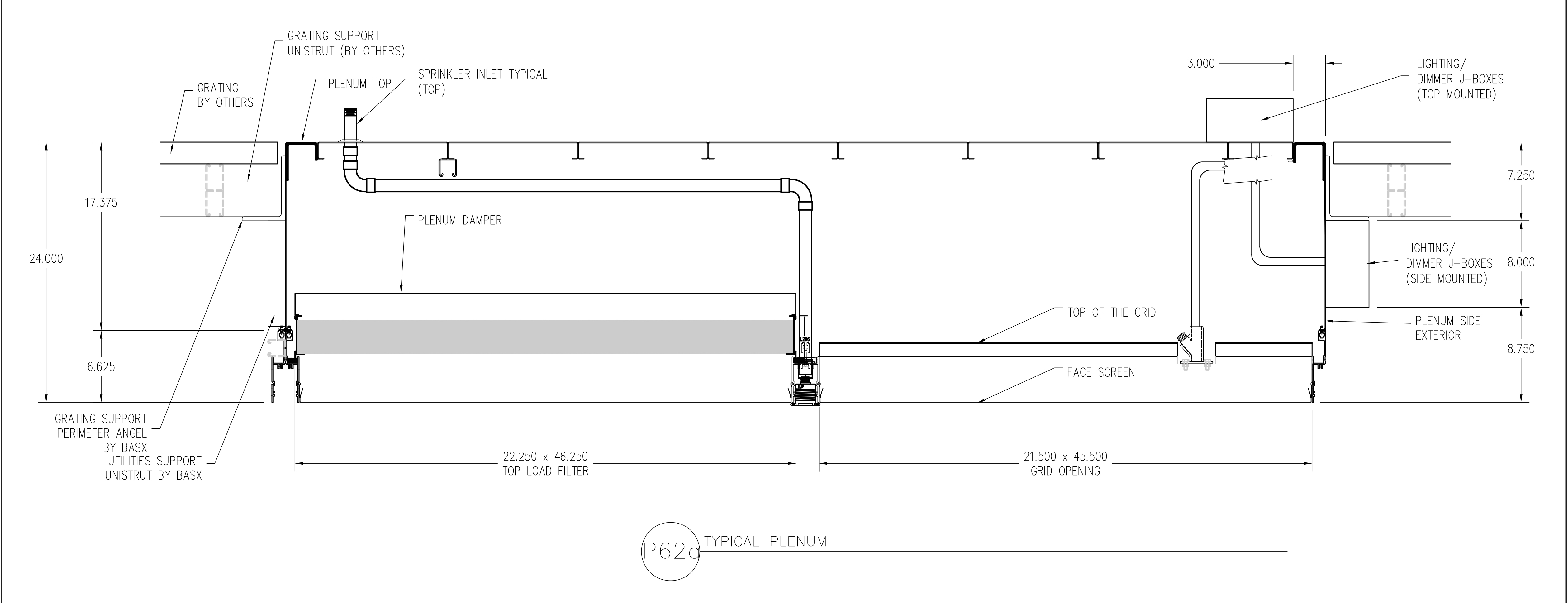

- Dimensions

- Interior (workspace) dimensions: width and depth as shown in diagrams; top of bench is 29.5” off floor

External dimensions: width and depth as shown in diagrams; total height is 83.38” with FFU & Pre-filter - Weight

- 2x4: Approx. 250 lbs with SS tabletop

2x8: Approx. 430 lbs with SS tabletop - Framework

- 2x2: heavy gauge tubular steel, 0.083” thickness, cold-rolled

Four bolt-together welded frames - Inset Panels

- 1/4” thick clear acrylic-standard, held in place using 2-part extruded PVC CleanSeal attachment system

- Plastic Shield

- 60 mil heavy-gauge clear flexible PVC, mounted using UniLock non-particulating attachment strip

- Fan Filter Unit (HEPA)

- 99.99% efficient on 0.3 micron particles, with solid state variable speed control for air velocity from 70 to 120 fpm (feet per minute) and a sound level of approximately 53 dbA measured 30” from the filter face

- Electrical

- Total draw from the unit: 3.8 Amps, 20 amp dual outlets (Qty. 2) and power switches are UL listed

Light and HEPA FFU are both UL listed as units, run at 60 Hz

6” power cord - Finish

- White baked polyurethane powder coating

Industries and Applications

- Research & Development

- Laboratories

- Semiconductor

- Microelectronics

- Pharmaceutical

- Biomedical

- Medical Device

- Injection Molding

- Photonics

- Automotive

- Aerospace

- Containment Suites

- Food Grade Packaging