Cooling Economizers

"Free cooling" is the process of extracting heat from the data center floor without using compressors to eject that heat to the outside. Turning compressors off greatly reduces the power draw required to remove heat. This is typically accomplished using relatively cold outside air to absorb heat directly from the data center space, the chilled water loop, or the refrigerant loop.

The type of economizer system to use depends on several criteria and is highly dependent on geography (average outside air temperature, altitude, humidity, etc). From an equipment design perspective, economizer efficiency has to do with approach temperature of the coil(s) and the maximum outside air temperature required in order to attain the desired temperature on the data center floor with the compressors turned off.

Low Approach Coils

Since CMS use custom, low-approach coils, our cooling units are able to provide free cooling with much warmer outside air temperatures. This means the cooling system can run in economizer mode (compressors turned off) for more hours during the year, i.e. more free cooling hours.

If low-approach coils are used on both the air-side and the water/refrigerant side, the outside air temperature needed in order to get free cooling can be raised by as much at 10-15 °F, which can result in a significant increase in the number of economizer hours.

Refrigerant Economizer on the Rise

CMS are seeing a significant increase of interest in refrigerant-based economizers. We think this is due to several factors:

- Outside air, while able to provide more hours of free cooling, often introduce problematic particulate matter to the data center space

- Issues around pressure are common which can also exacerbate the particulate issue

- The upfront and ongoing maintenance costs of maintaining a water loop, especially the cooling tower

CMS Economizer

CMS DESIGN AND MANUFACTURING OF CUSTOM "FREE-COOLING" SYSTEMS INCLUDING:

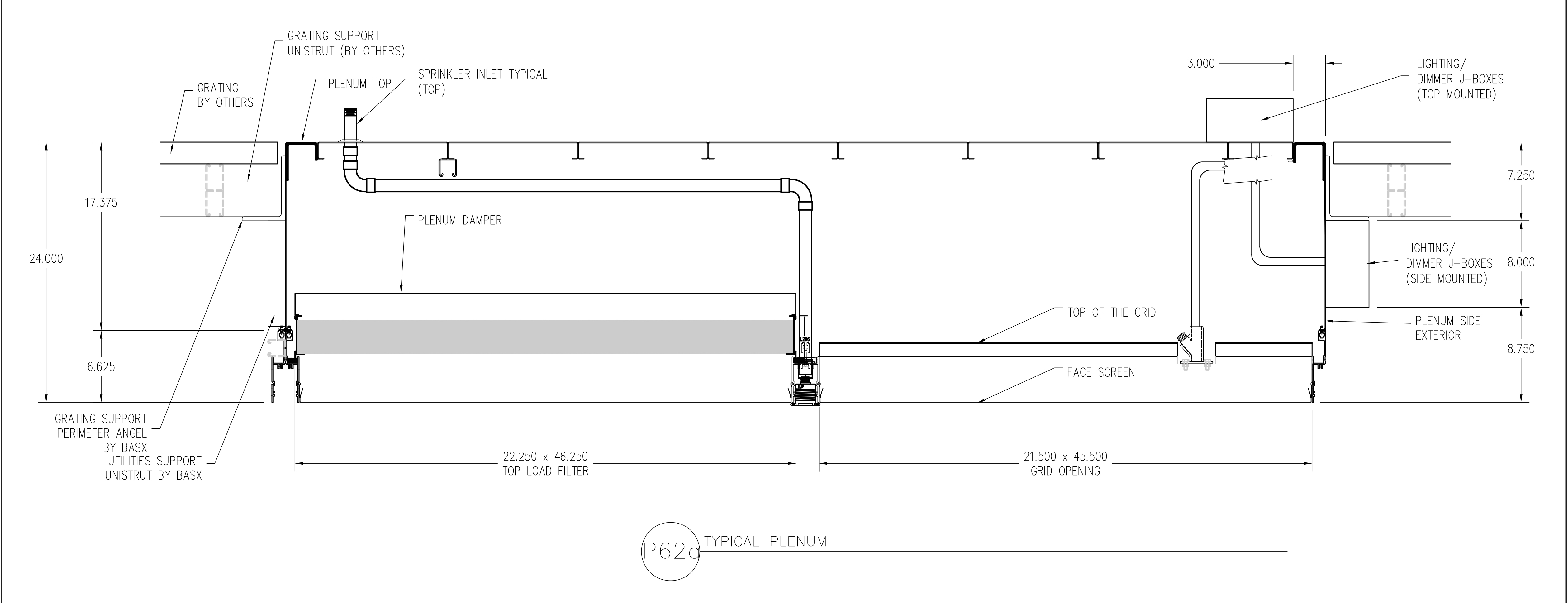

- Air-side economization

- Water-side economization

- Refrigerant economization

EXAMPLES

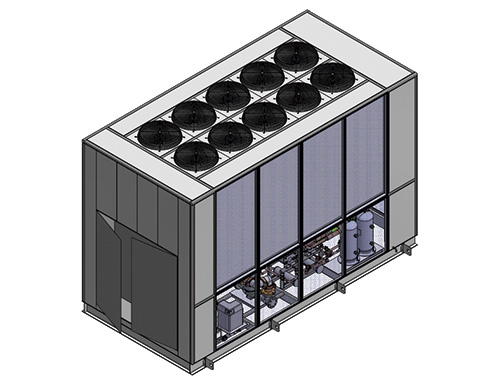

- 50-Ton DX unit with build in air-side economizer and combination relief + condenser

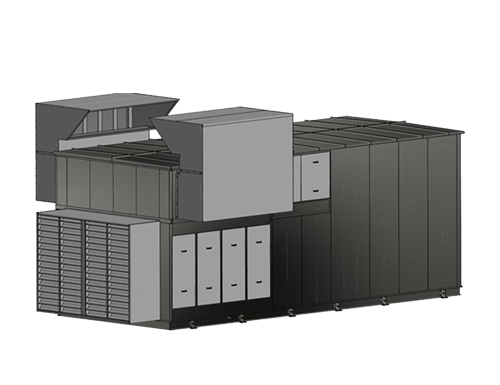

- 100-Ton DX unit with a pumped-refrigerant economizer that can make freely-cooled 70 °F supply air with 50 °F outside air.

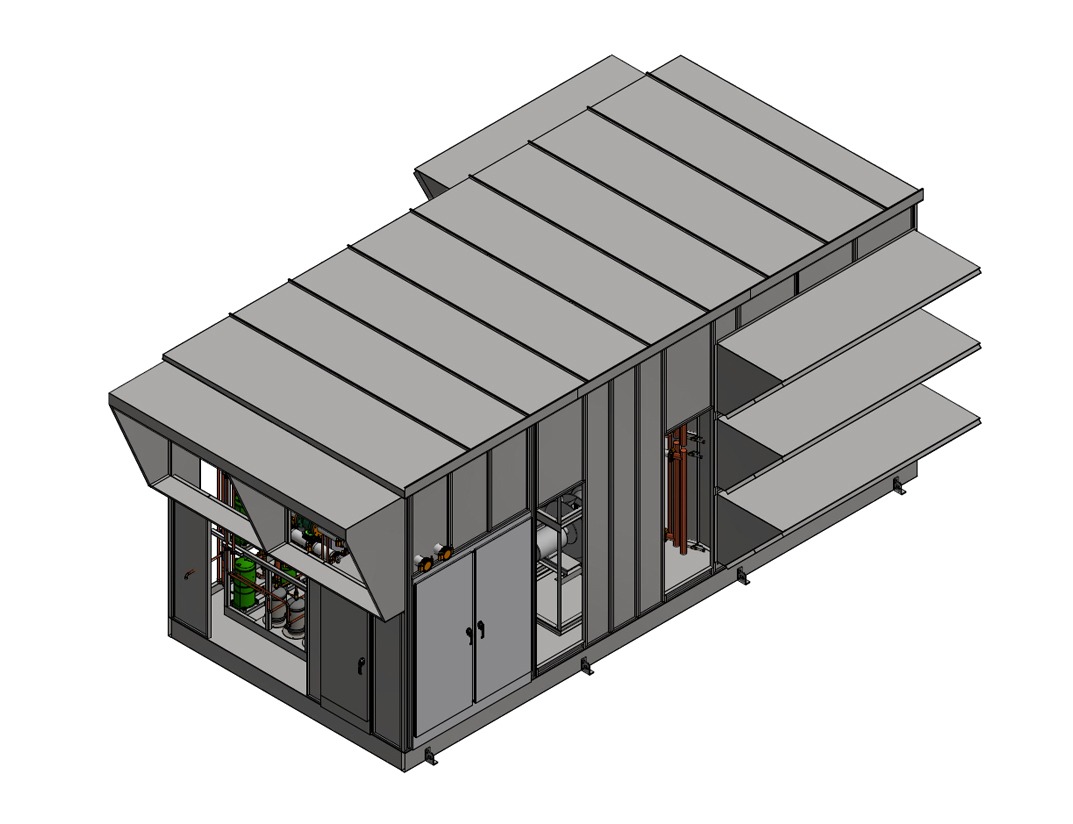

- 400-Ton Chiller with built-in water or refrigerant free-cooling coils